For

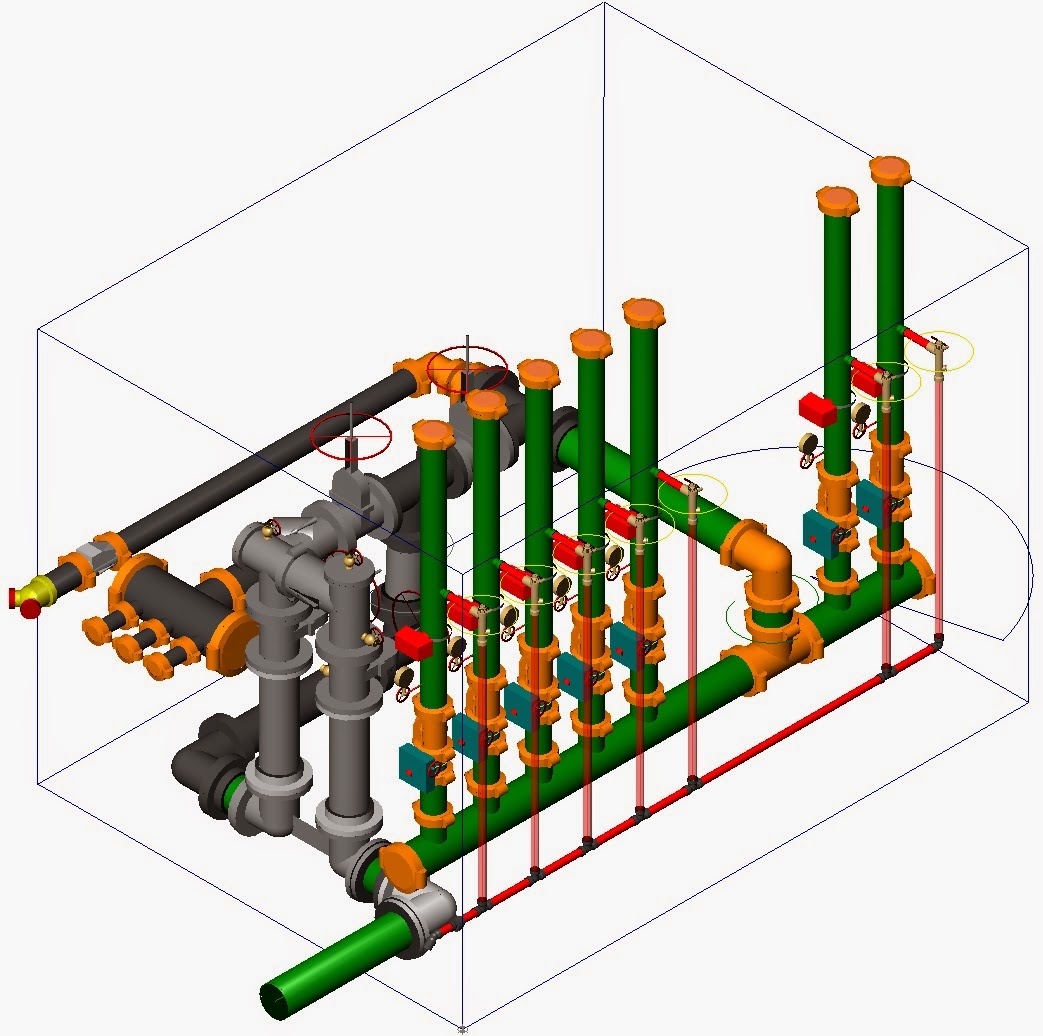

Fire Sprinkler designs, it is useful to have a 3D view to see what's going on. Yes,

it does take longer, but it may just be worth it in the end (cost/benefit

analysis). Besides, it's nice to be able to show someone what things look like

in 3D. It's one thing to hand someone a set of plans. It's quite another to

show someone a picture. The drawings below were done using AutoSprink, one of

the useful tools available in the industry.

Riser Room - SE Isometric View

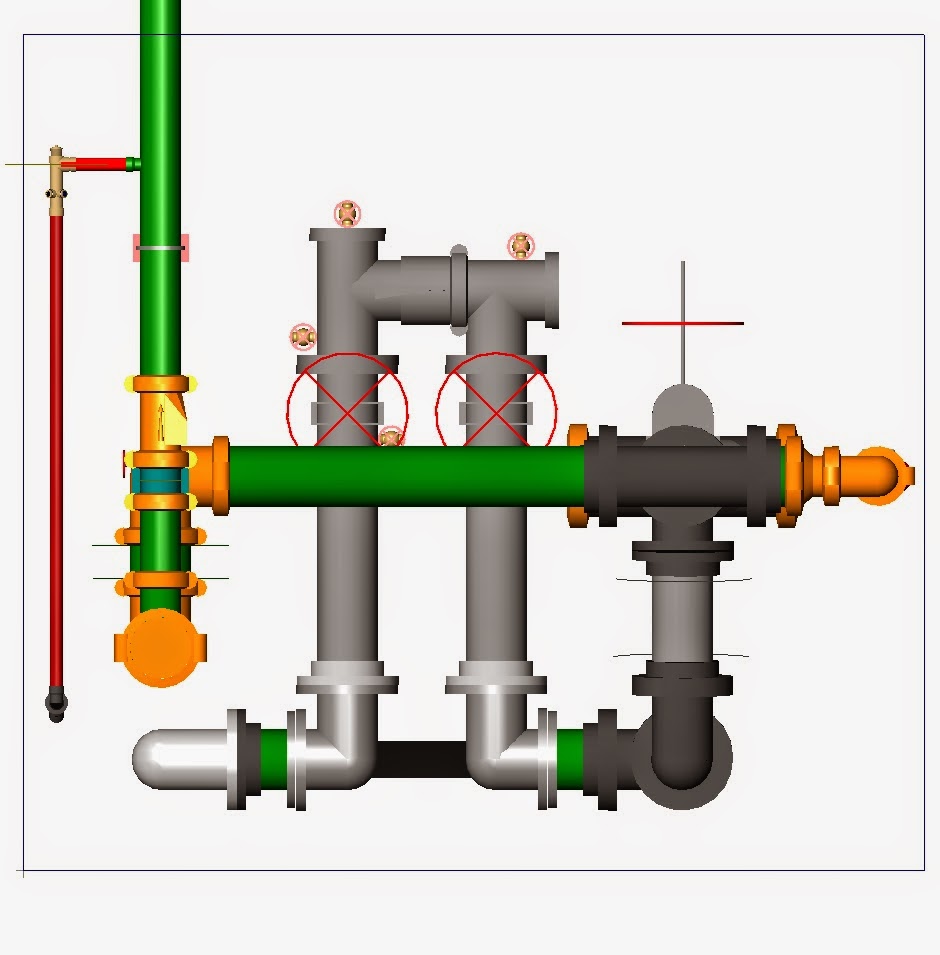

Riser Room - NW Isometric View

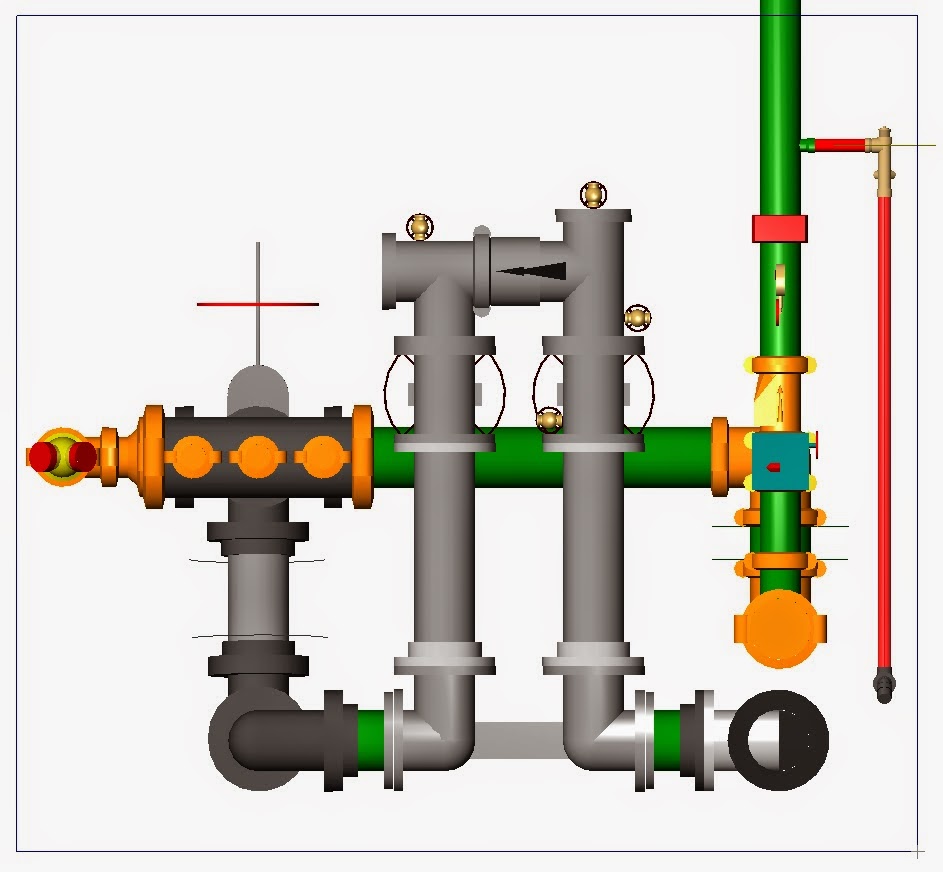

North View South View

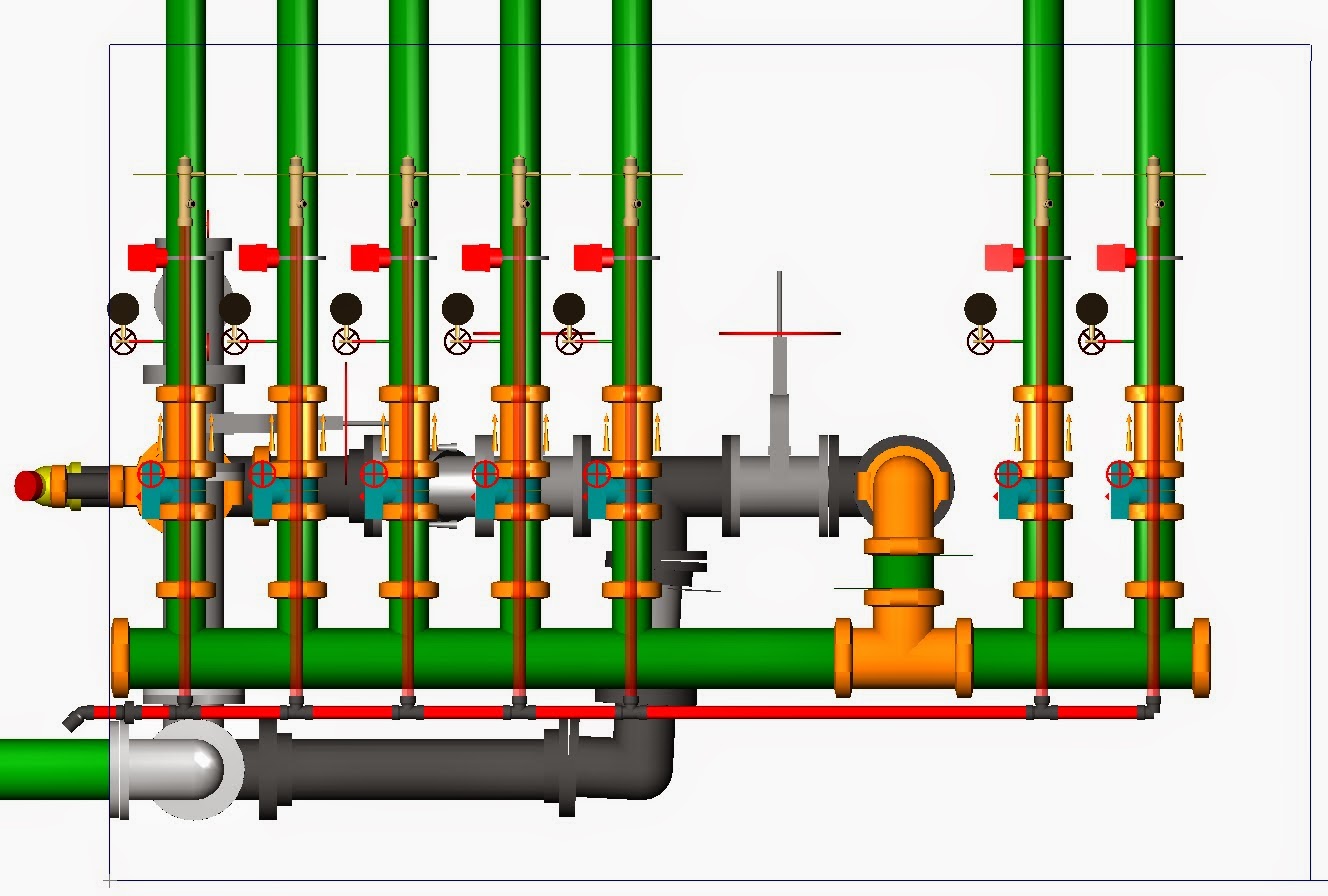

East View West View

Warehouse Sprinkler System Isometric View

Health Club Sprinkler System Isometric View